There, they happily removed their masks, pitched a tent, enjoyed the scenery, and played to their hearts’ content. Your sustainable engineered bamboo tiny home with flexible configurations, accessibility features, and off-grid options. In January 2021, they purchased a lot in Alfonso, Cavite. Since Haydee and her husband had been planning to buy land out-of-town as an investment, the pandemic became a catalyst for them to actually push through with it.

Cubo modular house tv#

“When the pandemic started, we had a five-year-old and a two-year-old who suddenly lost the right to play outside,” shared Haydee Bellen-Serrano, a TV scriptwriter, who admitted she resorted to buying more toys to try to compensate for the dire situation. It was unsettling, and parents couldn’t help but be worried over their children’s development. The entrepreneurs behind Cubo Modular are Earl Patrick Forlales the CEO and Zahra Halabisaz Zanjani the COO. The Bulacan Loft features a spacious loft level that can fit a large queen bed and a floor desk. Cubo Modular is a modular engineered bamboo housing designer and manufacturer that is known for making small houses that can be assembled in just a matter of hours.

Cubo modular house series#

The series of constant lockdowns and restrictions had been hard on Filipino families, especially the kids, who were forced to stay indoors. This video is about the award-winning model of Cubo modular which is the Bulcan Loft model.

Cubo modular house free#

The manufacturer states the prefabrication process of a house takes approximately four weeks, and the delivery and installation including finishing between three to four weeks.SHOW CAPTION HIDE CAPTION Where kids can roam free The foundation is built on-site and the house is prefabricated in a factory and then assembled on-site. The ceiling is built using a light steel framing and fiber cement board and the roof is composed of galvanized steel sheet trusses and insulated sandwich roof panels. Affordability comes as a result of this movement toward a more sustainable material, Forlales says. earl patrick forlales, the 23-year-old behind the project, has also developed a business plan that will provide local people with housing, new skills, jobs. With a total livable space of 30.5sqm, it’s the best starter home for young couples and small families.

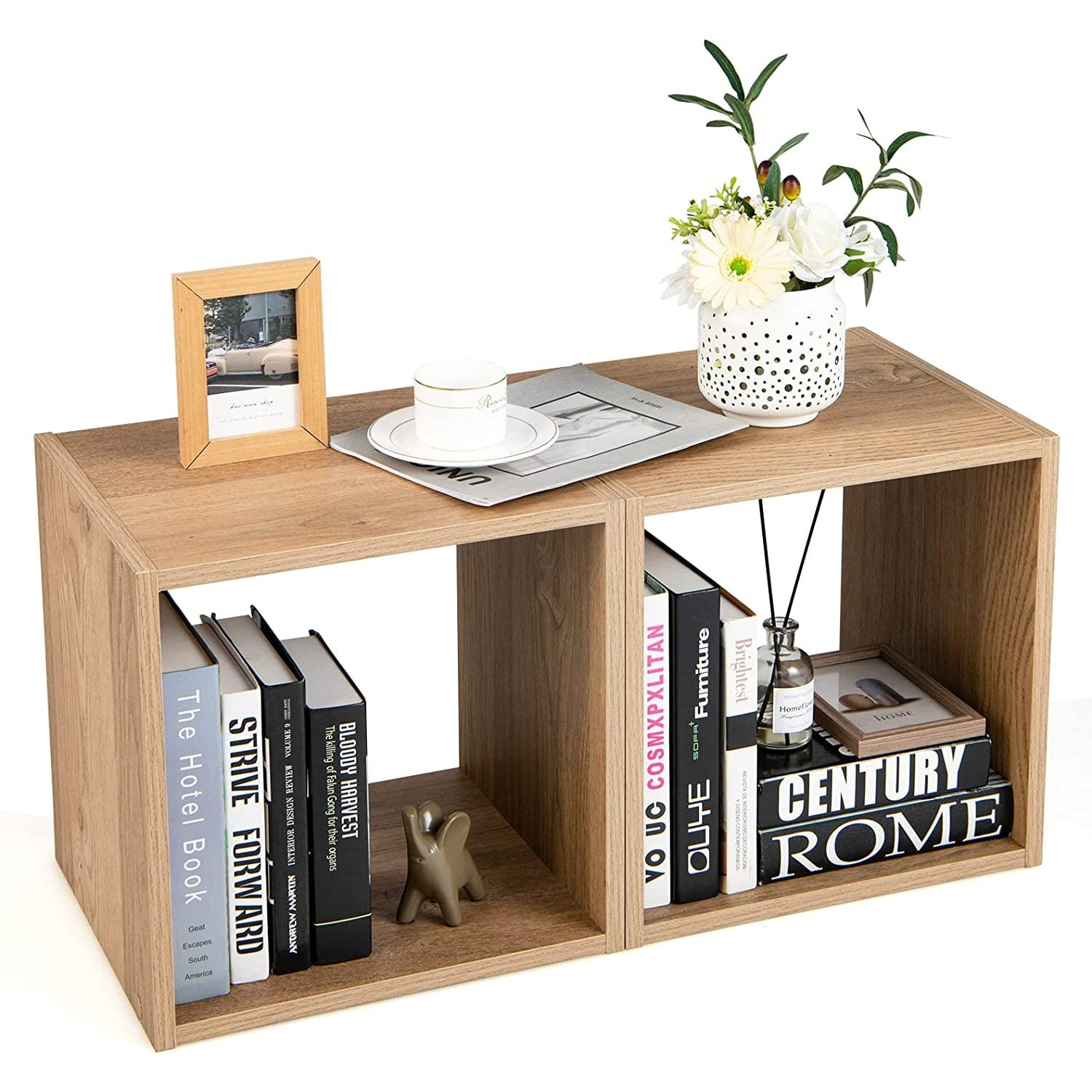

The house uses industrialized construction materials available in the local market such as reinforced concrete for the foundations, plain galvanized steel for structural columns, wall, floor, and roof, fiber cement boards and expanded polystyrene sandwich boards for the walls. CUBO’s modular houses are currently priced between 300 and 500 per square meter, but the start-up aims to bring that cost down to 200 per square meter within the next five years. A Cubo Modular Home IMAGE Cubo Modular The photo above shows Cubo Modular’s 2022 Bulacan Starter Home, a gem of a space that can sleep around four people, has loft and studio bedrooms, and a modern bathroom. However, the building system could adapt to particular designs. CUBOs modular houses are currently priced between 300 and 500 per square meter, but the start-up aims to bring that cost down to 200 per square meter within. The manufacturer offers nine pre-designed house models that vary between 36 to 73.5 m² and houses families of two to five members.

Bahay Makayaban is a prefabricated, modular, and customizable housing system that is designed and produced in the Philippines by the Hecthor Building and Housing Solution Corporation.

0 kommentar(er)

0 kommentar(er)